Children’s Mercy Research Institute

Building for the future of pediatric medicine

In February 2021, Children’s Mercy announced the opening of its newest pediatric research facility — the Children’s Mercy Research Institute® (CMRI). Established in 2015, CMRI focuses on accelerating precise diagnoses and treatments for complex childhood diseases, moving kids to the forefront of research discoveries.

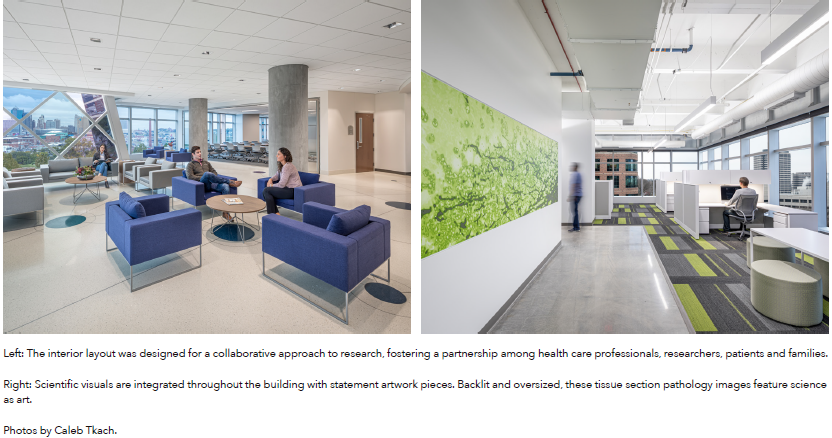

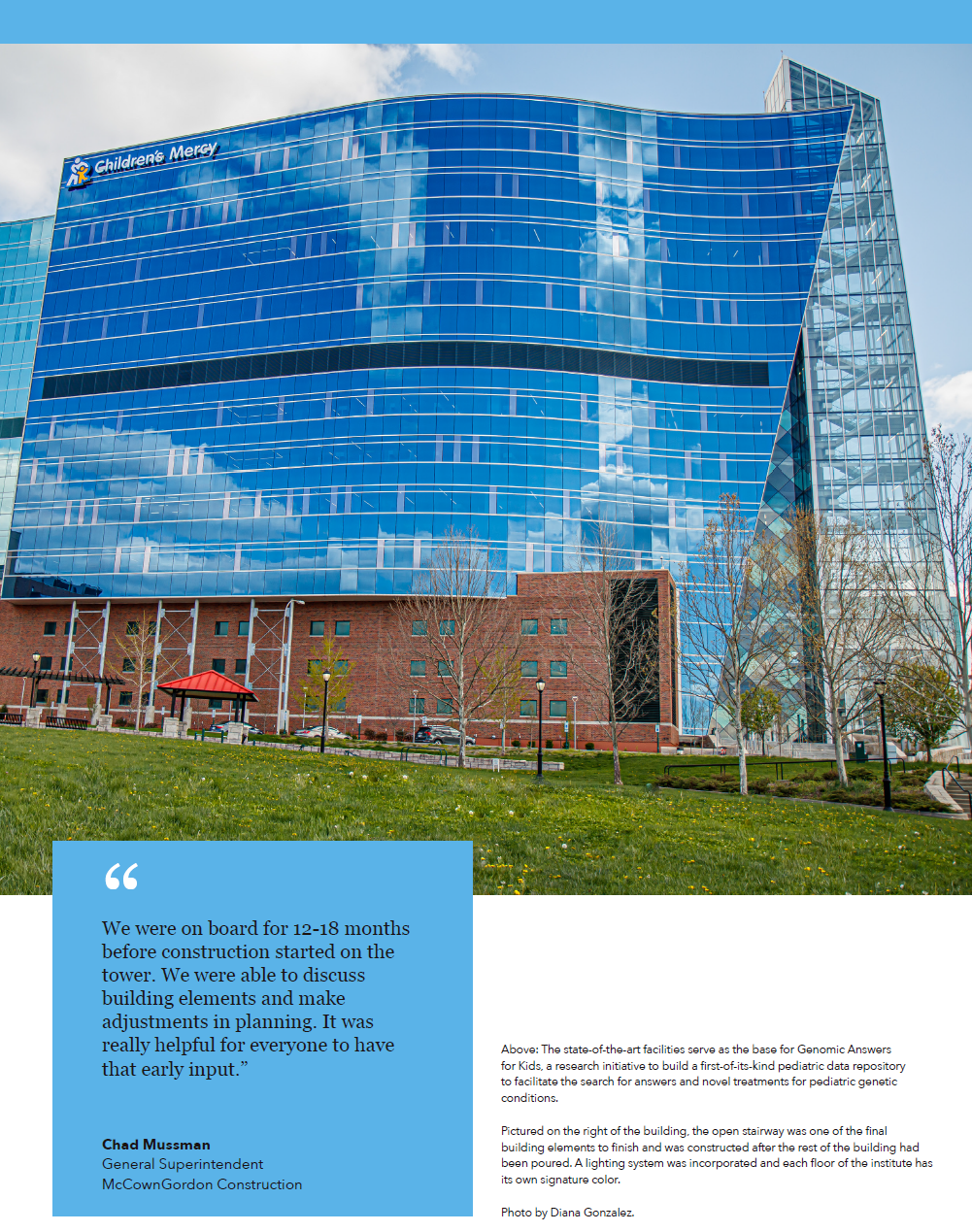

Near the heart of downtown Kansas City, the CMRI building has quite the presence. With a sleek, 12-inch-deep curtain-wall system and a nine-story open stairway shaped like a DNA helix, it’s impossible not to appreciate the design of this building. But the most impactful exterior design features are the DNA sequences of four Children’s Mercy patients displayed on the all-glass façade. The windows represent the genetic anomalies and are illuminated at night. This unique element demonstrates the building and design team’s focus on creating a building almost as impressive as what goes on inside.

Early collaboration

The key players in the creation of such an important building were brought together early in the preconstruction phase.

“We were on board for 12-18 months before construction started on the tower,” Chad Mussman, general superintendent at

McCownGordon Construction, said. “We were able to discuss building elements and make adjustments in planning. It was really

helpful for everyone to have that early input.”

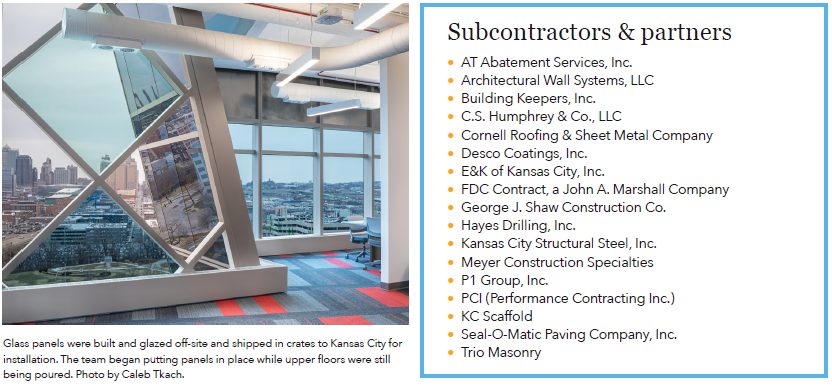

One of the most significant preplanning challenges was identifying the best approach for the glass curtain-wall system. The team

ultimately determined a modular system was ideal and brought Architectural Wall Systems on board early to help guide the

planning. The 5-foot-wide sections were built and glazed at a facility in Toronto, then shipped in crates to the site. Each of the 1,660

individual curtain sections was pre-sealed and clicked into place, like building blocks.

“We were nervous about what could go wrong here,” Anwar Garcia, project executive at McCownGordon, said. “But there were very

few adjustments, thanks in part to the incredibly detailed modeling done by Architectural Wall Systems.”

Glass began arriving on-site and ready to install as the floors were still being poured. Each floor was four concrete pours, with the

exception of the first floor, which was five. Once the team reached the fifth of the nine floors, the curtain-wall system installation

began.

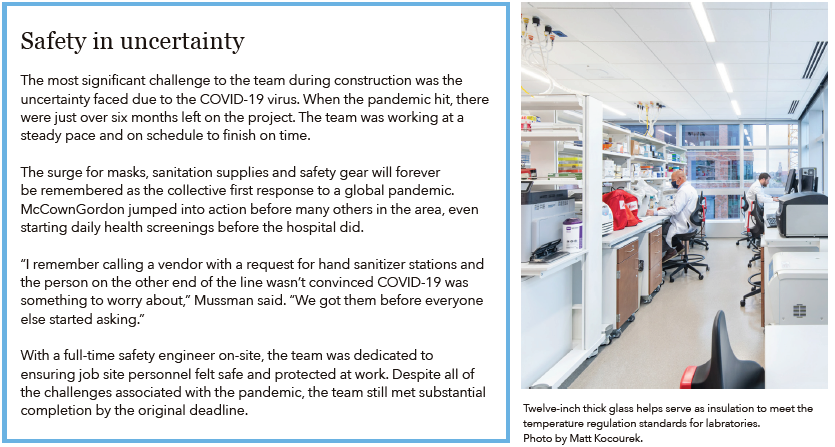

The glass curtain wall does more than create an impressive façade. The tower was designed for optimal energy efficiency and the

12-inch deep curtain-wall system serves as continuous insulation, which helps regulate the temperature. Due to the nature of the

work done inside, this was key. In addition, an 8-by-8-foot “glass box” vestibule separating the building’s main entrance from its

interior helps reduce the strain on heating and cooling systems as occupants enter and exit.

The stairwell was another element that evolved from its original design in the preplanning process. Initially designed as a concrete

spiral staircase, early discussions led to revising the design to structural steel attached to concrete, which leans in and narrows as it

goes up. It was one of the last areas to finish and a critical item for the schedule. Detailed 3D modeling was key in the design and

construction of the stairwell.

Flexible approach

Even with significant upfront work in the preconstruction phase, the project was not without scheduling challenges. When the

team broke ground on the project, they had planned to relocate known underground utilities to accommodate the new building. A

surprise discovery of fiber on the property east of where it was expected pushed the team to adjust the sequencing to address the

challenge. Since it fed into government facilities and other undisclosed users, it couldn’t just be turned off and turned back on.

“We immediately paused and regrouped to figure out this issue,” said Mussman. “It totally changed the sequence of how we poured

the structure, but the team was able to find a solution without a significant impact to the schedule.”

The new CMRI tower was built atop an existing functioning parking garage, adding another layer of complexity to the project.

Fortunately, the garage had been engineered to support a nine-story building, but it was necessary for the parking garage to remain

functional with only the top floor available for job-site needs. Beyond the limited lay down, there was also a strategic approach to

choosing the type and placement of the cranes for the project.

“We needed the cranes to reach the entire area and where we had lay down,” Mussman said. “The project naturally lent itself to

being a two tower-crane job.”

Community impact

It’s easy to get caught up in the construction process and forget about the end-use for a building. The close collaboration among

the design team with Children’s Mercy stakeholders kept the importance of this building at the forefront for everyone at the job site.

“We are so used to building every day that sometimes we have blinders on and forget about what impact the facility will have once

completed,” Garcia said. “The Children’s Mercy team was very engaged throughout the process and walking the job site with them

really helped drive the importance of this project home.”

Already the work done at CMRI is making an impact on pediatric health across the country. McCownGordon and the team are proud

to have played their part in standing up another iconic building in the Kansas City metro.